OUR HVAC PROJECTS

Successful commissioning completed at Fazal Cloth – Unit 2 (Autocone Department)!

Our first HVAC project with Fazal Group achieved remarkable energy optimization, reducing the running load from 84 kW to just 25 kW while improving conditions.

We are delighted to announce the successful commissioning of the HVAC plant at Fazal Cloth – Unit 2, Autocone Department. This project marks a significant step forward in delivering state-of-the-art climate control and energy-efficient solutions for the textile sector.

The newly commissioned system is now running seamlessly, ensuring that all critical parameters—including temperature, relative humidity, air changes, and air volume—are being maintained with exceptional precision. By achieving this level of control, we are not only enhancing the overall production environment but also ensuring better product quality, consistency, and operational efficiency within the department.

Project Update | Intelligent HVAC System at Nisar Spinning Mills Pvt. Ltd

We are thrilled to share our first collaboration with Nisar Spinning Mills Pvt. Ltd., where our team is implementing a Jingya Intelligent HVAC System to upgrade the Ring AC section.

This ongoing project is a step toward smarter and more energy-efficient operations, ensuring optimal temperature control, reduced energy consumption, and enhanced system reliability.

Our Engineers are working diligently as the project moves toward successful completion.

Here’s a glimpse of the progress so far!

We are proud to announce the continued progress of our HVAC Intelligent System installation at Sapphire Textile Mill Unit 4 (STM-4).

Backprocess Plants have been successfully installed at both Sapphire and Ghulshan units.

Work is actively underway on the Ring and Autocone Plants, marking another step forward in our mission to transform STM-4 into a fully intelligent and energy-efficient climate control facility.

This project reflects our commitment to delivering:

Optimized energy efficiency to reduce operational costs

Precise temperature & humidity control for improved textile quality

Reliable automation solutions tailored to industrial needs

Sustainable operations aligned with modern environmental standards

With every phase, we move closer to completing the whole-mill AC modification, ensuring a smarter and more sustainable production environment for the textile sector.

A big thank you to our dedicated team and partners for making this vision a reality.

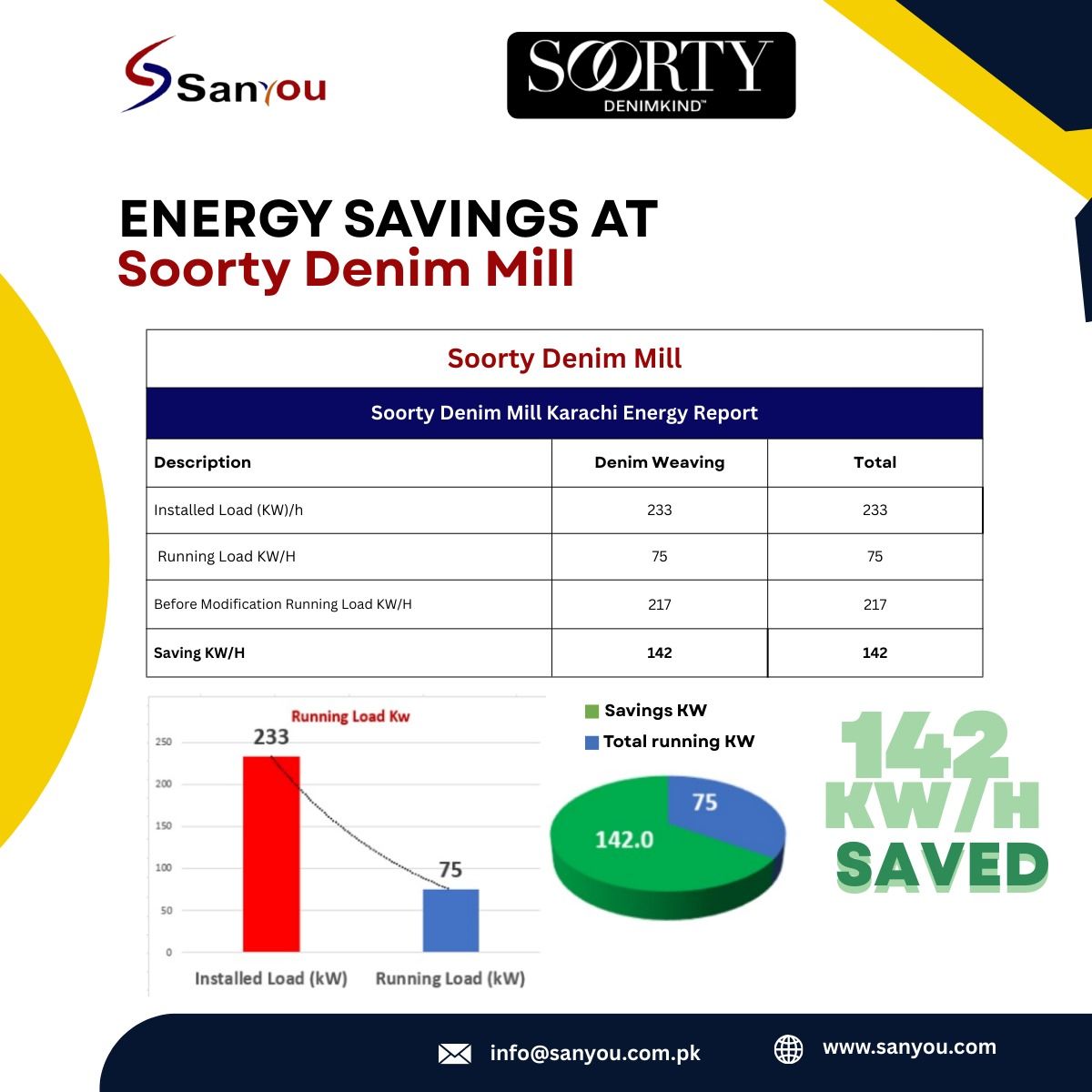

We’re proud to share the remarkable energy savings achieved at Soorty Denim Mill with the support of Sanyou solutions.

Through our innovative energy optimization solutions, the mill has achieved an outstanding transformation — reducing its running load from 217 KW/H down to just 75 KW/H. This remarkable improvement translates into 142 KW/H saved every single hour of operation.

Such a milestone is not just about numbers. It represents a powerful step towards sustainable manufacturing, significantly lowering operational costs while minimizing the environmental footprint.

At Sanyou, we believe in driving progress for the textile industry and beyond. Our mission is to help industries enhance performance, maximize efficiency, reduce energy expenses, and contribute to a greener, more responsible future.

At Suraj Cotton, our energy optimization project has successfully reduced the running load from 378 KW/H to just 115 KW/H, resulting in an impressive 263 KW/H savings

At Suraj Cotton, our latest energy optimization project has delivered outstanding results — reducing the running load from 378 KW/H to just 115 KW/H, achieving an impressive 263 KW/H in energy savings.

This remarkable achievement goes beyond cost reduction; it represents a major step towards energy efficiency, operational excellence, and long-term sustainability in the textile industry.

By embracing smarter and greener solutions, Suraj Cotton continues to set new benchmarks for responsible manufacturing. Together, we are not only saving energy but also building a future where innovation and sustainability go hand in hand.

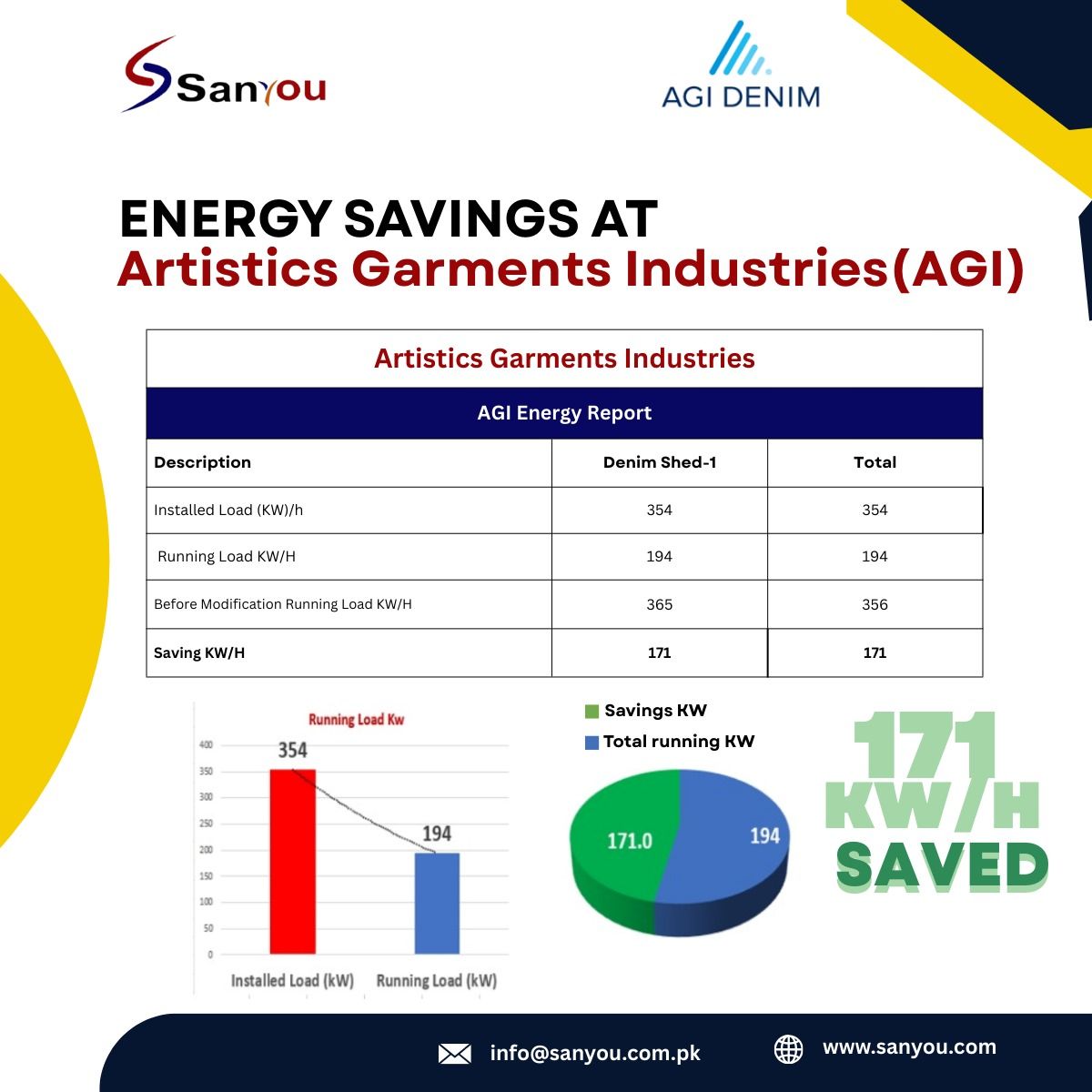

At Artistics Garments Industries (AGI), our modification project successfully reduced the running load from 365 KW/H to 194 KW/H, achieving a remarkable 171 KW/H in energy savings.

At Artistics Garments Industries (AGI), our latest modification project has delivered impressive results — reducing the running load from 365 KW/H to 194 KW/H, achieving a remarkable 171 KW/H in energy savings. ⚡✅

This success is a strong reflection of our commitment to innovation, sustainability, and cost efficiency within the textile sector. By optimizing energy consumption, we not only lower operational costs but also reduce the environmental footprint, contributing to a more sustainable future. 🌍💡

Together with our partners, we’re driving smarter, greener, and more efficient manufacturing practices that benefit both industry and the environment.

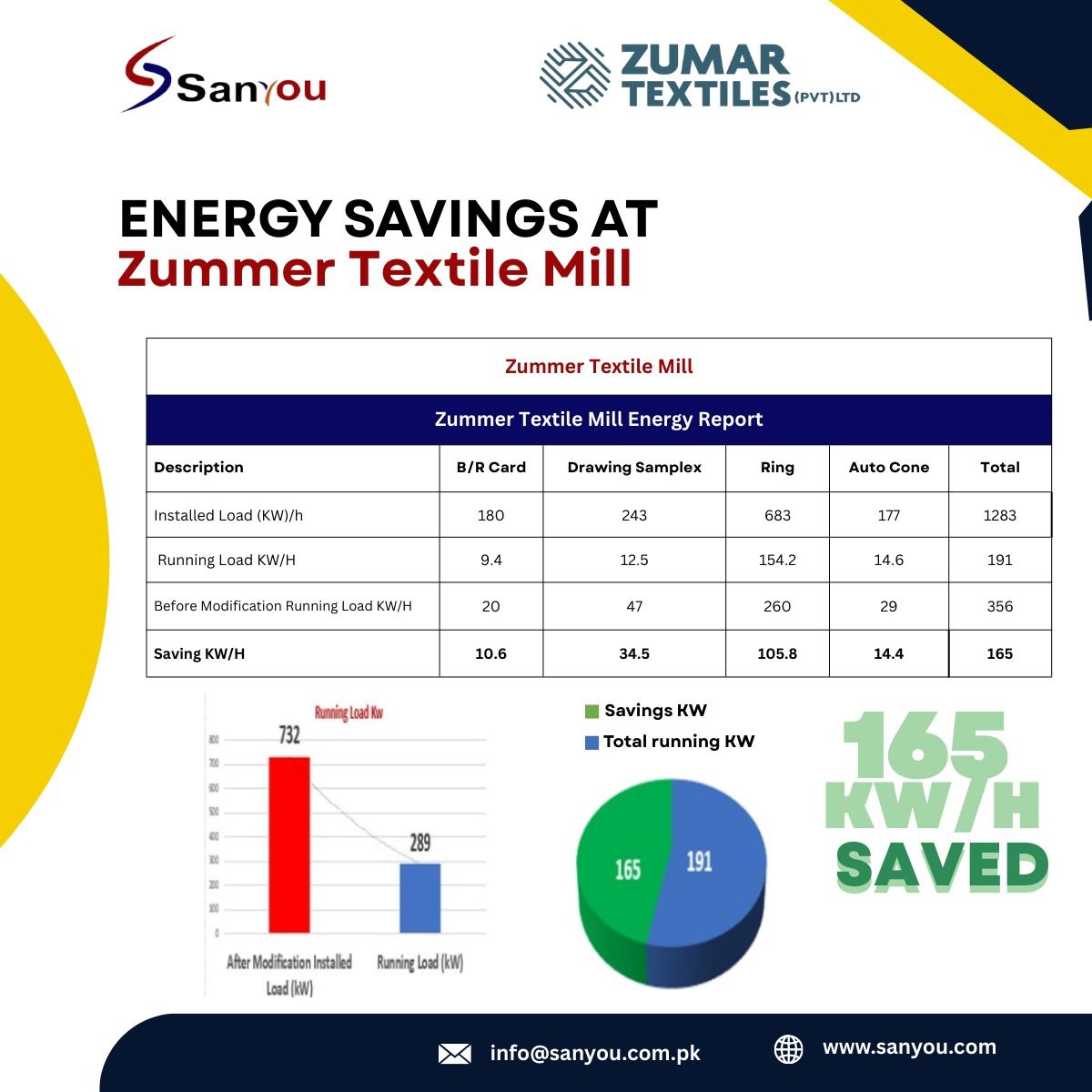

Our recent project at Zummer Textile Mill has delivered exceptional results in energy efficiency and sustainability:

✅ 165 KW/H energy saved across operations

✅ Running load reduced from 356 KW/H to just 191 KW/H

✅ Significant savings achieved in B/R Card, Drawing Samplex, Ring, and Auto Cone units

Through the implementation of smart automation and advanced energy-efficient technologies, we’re helping our partners unlock lower operational costs, enhanced productivity, and a greener future. 🌍💡

At Zummer Textile Mill, this achievement reflects the growing impact of sustainable innovation in shaping the textile industry of tomorrow.

.

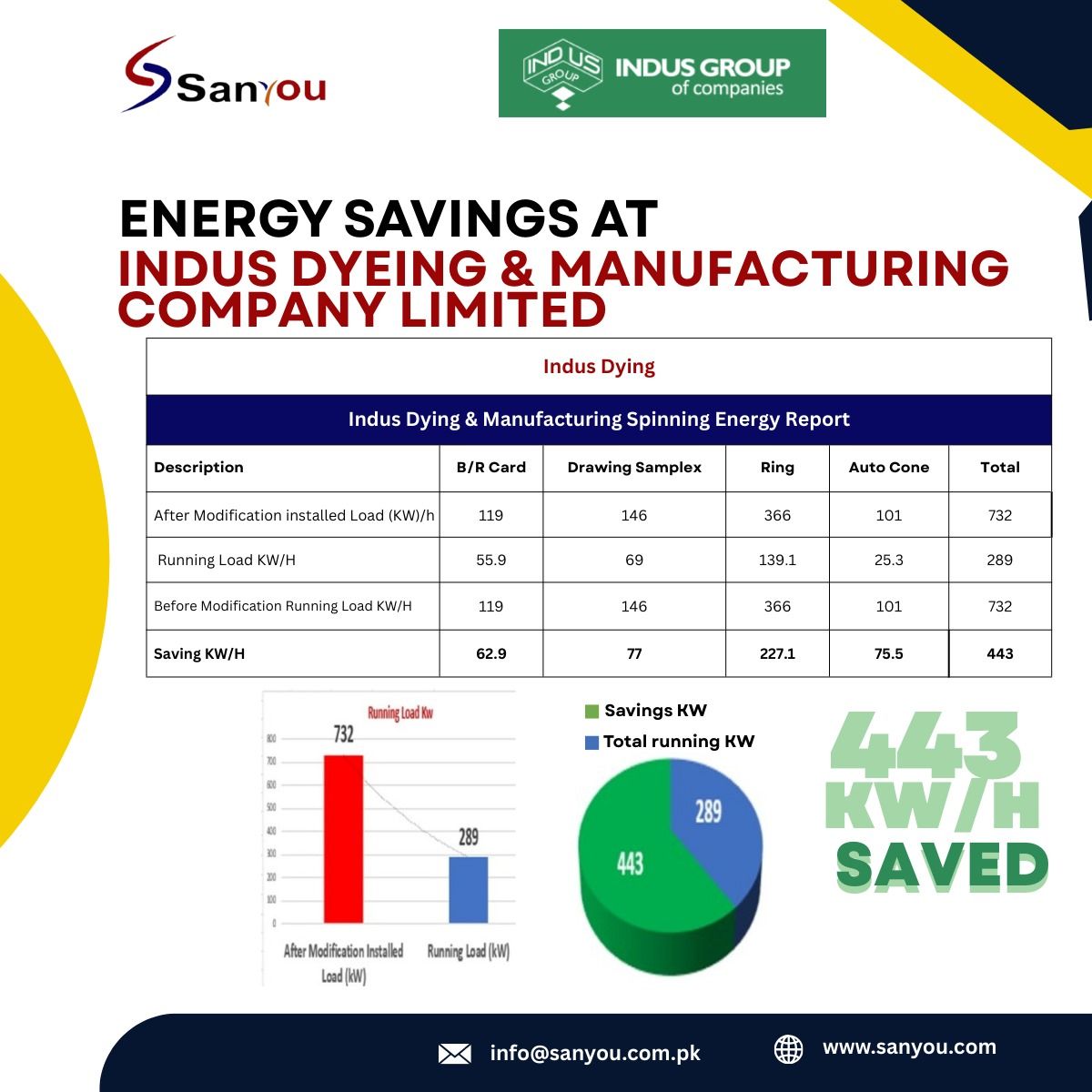

Energy Savings Achieved at Indus Dyeing & Manufacturing Company Limited!

With Sanyou’s innovative energy optimization solutions, Indus Dyeing has successfully reduced its running load from 732 KW/H to just 289 KW/H, delivering an impressive 443 KW/H in energy savings. ⚡✅

This milestone is more than just numbers — it demonstrates our shared commitment to sustainability, operational efficiency, and significant cost reduction in the textile sector.

Together, we are driving smarter, greener, and more responsible manufacturing practices, shaping the future of the industry.

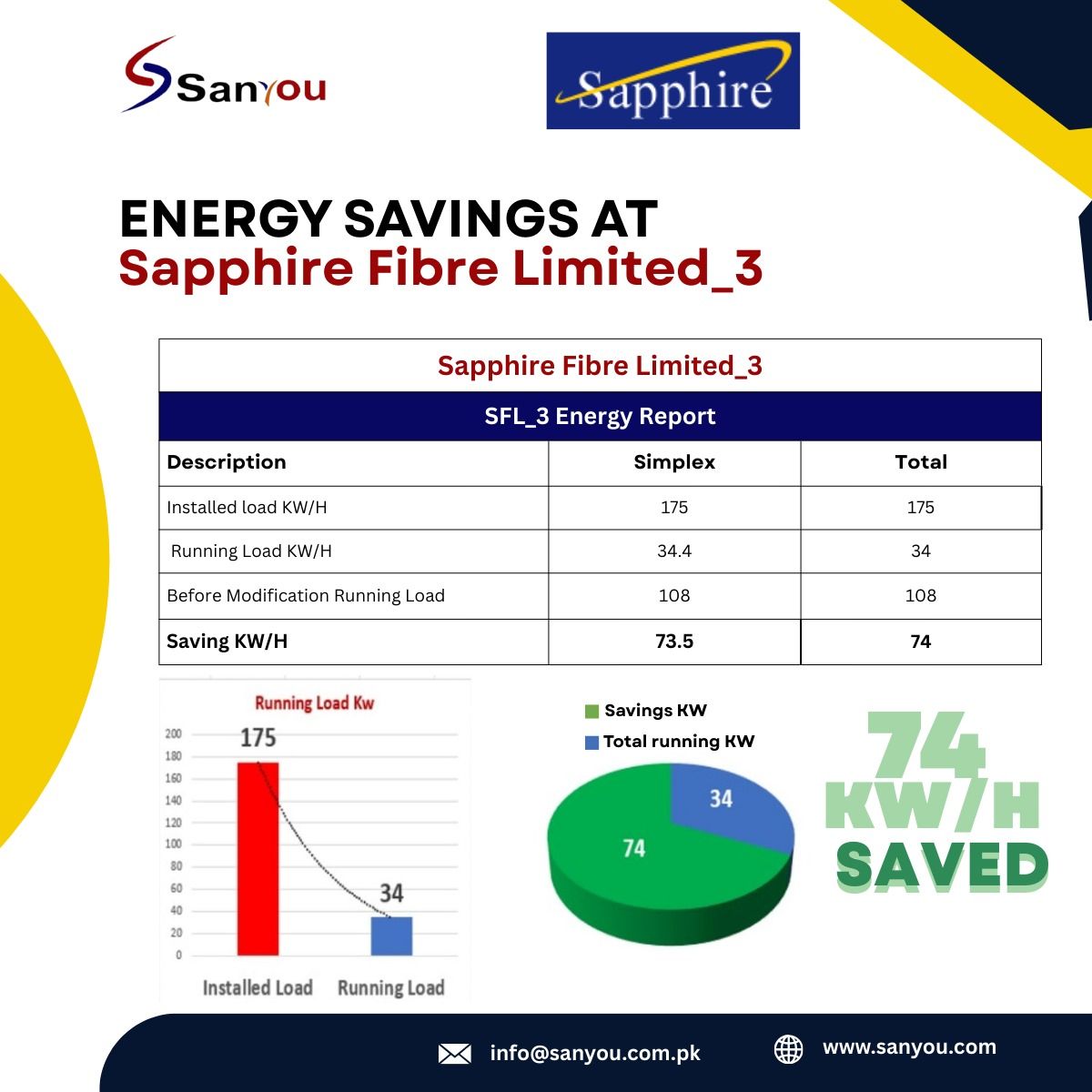

Energy Savings at Sapphire Fibre Limited_3

Through advanced energy optimization and system modifications, Sapphire Fibre Limited_3 has achieved remarkable power savings across its operations.

Energy Report Highlights:

✅ Installed Load: 175 KW/H

✅ Running Load (Before Modification): 108 KW/H

✅ Running Load (After Modification): 34 KW/H

✅ Total Savings: 74 KW/H

This achievement reflects Sapphire Fibre Limited’s strong commitment to sustainable practices, cost efficiency, and energy conservation—delivering both a reduced environmental footprint and improved operational efficiency.

At Sanyou, we take pride in partnering with leading textile mills to optimize energy usage, reduce costs, and enhance performance—paving the way for a greener, smarter future for the industry.

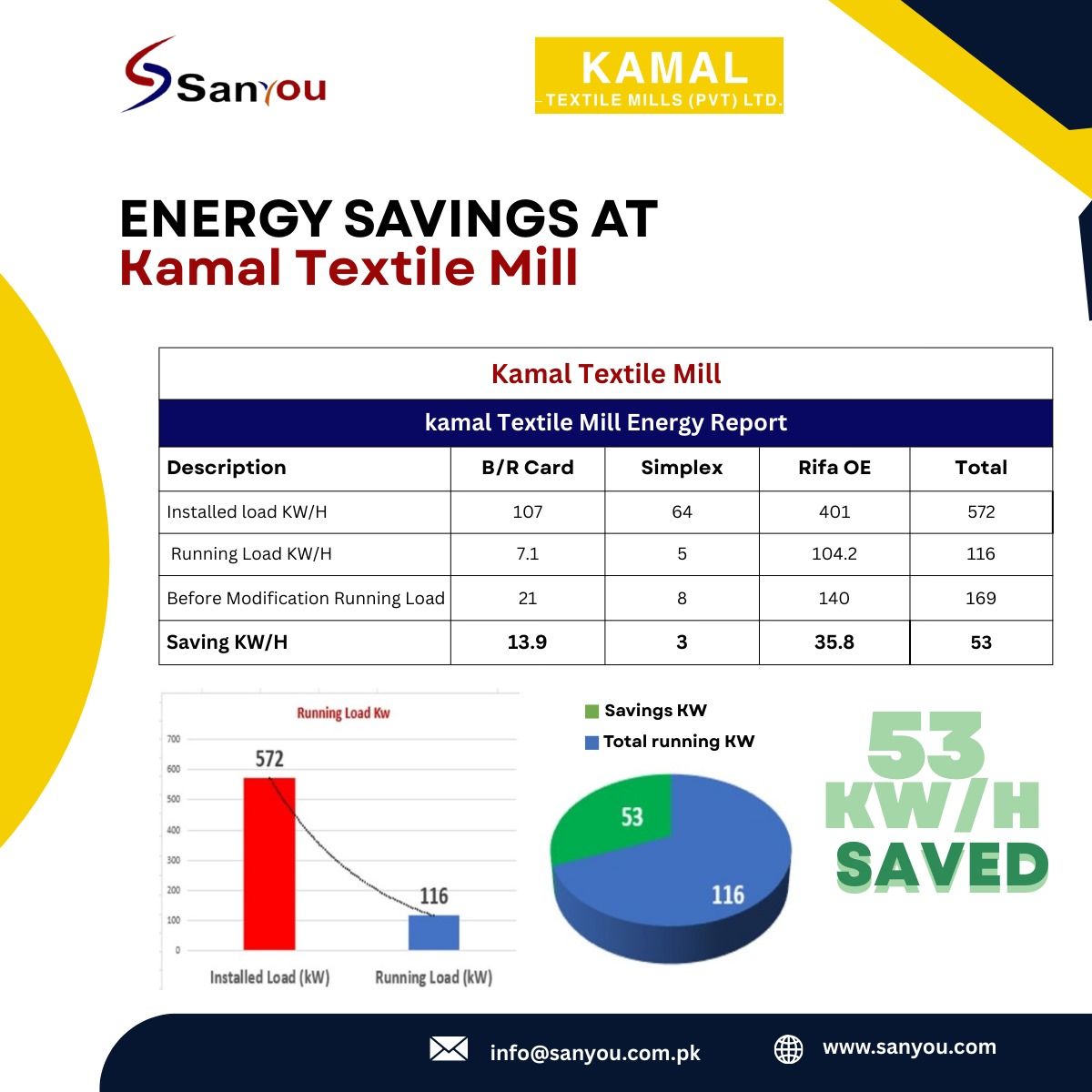

Energy Savings Achieved at Kamal Textile Mill!

We are pleased to share another remarkable success in energy optimization. At Kamal Textile Mill, our innovative solutions reduced the running load from 169 KW/H (before modification) to just 116 KW/H, achieving an impressive 53 KW/H in energy savings. ✅

This improvement not only lowers operational costs but also reinforces the shift towards sustainable, eco-friendly textile production. By integrating smart energy practices, we are helping industries embrace efficiency, innovation, and greener growth.

At Sanyou, we remain committed to empowering the textile sector with smarter energy solutions for a more sustainable future.

stry.

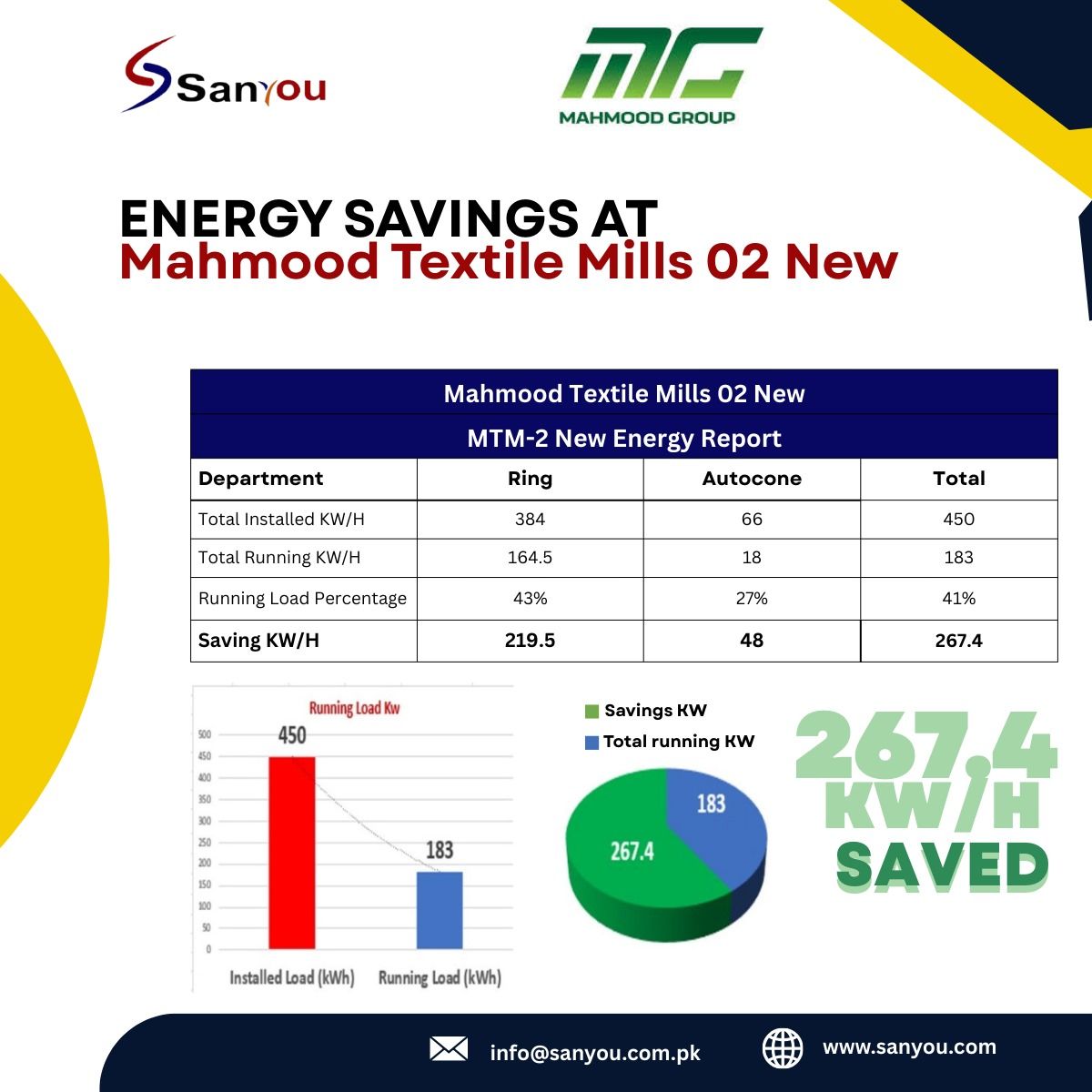

Energy Savings Achieved at Mahmood Textile Mills (MTM-2 New Unit)!

We’re proud to announce another remarkable milestone in energy optimization.

Results at a Glance:

✅ Total Installed Load: 450 KW/H

✅ Total Running Load (After Optimization): 183 KW/H

✅ Running Load %: 41%

✅ Total Energy Saved: 267.4 KW/H

By optimizing systems and reducing unnecessary load, we have achieved over 59% energy savings—a significant step toward sustainable, cost-efficient, and eco-friendly operations.

At Sanyou, we remain dedicated to delivering innovative energy solutions that empower the textile industry to reduce costs, enhance efficiency, and contribute to a greener future.

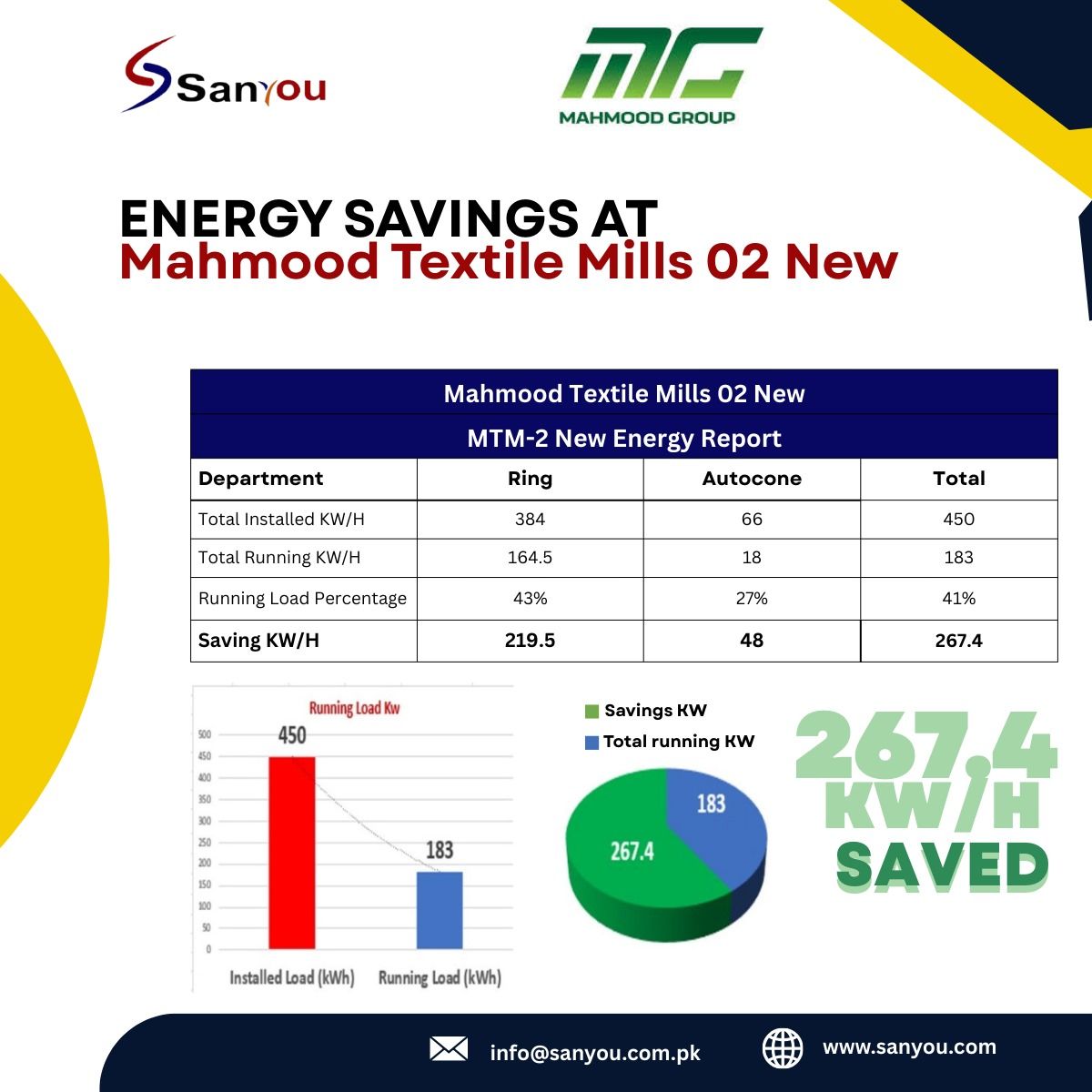

Energy Savings Achieved at Mahmood Textile Mills (MTM-2 New Unit)!

We’re proud to announce another remarkable milestone in energy optimization.

Results at a Glance:

✅ Total Installed Load: 450 KW/H

✅ Total Running Load (After Optimization): 183 KW/H

✅ Running Load %: 41%

✅ Total Energy Saved: 267.4 KW/H

By optimizing systems and reducing unnecessary load, we have achieved over 59% energy savings—a significant step toward sustainable, cost-efficient, and eco-friendly operations.

At Sanyou, we remain dedicated to delivering innovative energy solutions that empower the textile industry to reduce costs, enhance efficiency, and contribute to a greener future.